|

CH-47-04-02 |

| Following combat operation of CH-47D aircraft in Iraq and in the mountains of Afghanistan, pilots reported that continuous flight operations were conducted with the cruise guide indicator (CGI) in the transient region, accompanied by excursions into the avoid region, usually encountered in turbulence. |

UNCLASSIFIED

.

MSG DTG 291415Z APR 04

.

FROM CDRAMCOM, REDSTONE ARSENAL, AL //AMSAM-SF-A//

.

SUBJECT - AVIATION SAFETY ACTION MESSAGE, MAINTENANCE MANDATORY,

.

RCS CSGLD-1860(R1), ALL CH-47D AIRCRAFT, TRANSIENT AND AVOID

.

BANDS ON THE CRUISE GUIDE INDICATOR, CH-47-04-ASAM-02.

.

...................NOTE...................

....This message is effective until rescinded or superseded.

...................NOTE...................

....This message is issued IAW AR 95-1 and has not been

....transmitted to units subordinate to addressees.

....Addressees will immediately retransmit this message

....to all subordinate units, activities or elements

....affected or concerned. MACOMs will immediately

....verify this transmission to the AMCOM SOF Compliance

....Officer (AMSAM-SF-A, safeadm@redstone.army.mil).

...................NOTE...................

....MACOM commanders may authorize temporary exception from

....message requirements IAW AR 95-1, Ch 6. Exception may

....only occur when combat operations or matter of life or

....death in civil disasters or other emergencies are so

....urgent that they override the consequences of continued

....aircraft operation.

1. SUMMARY -

1.1. BACKGROUND -

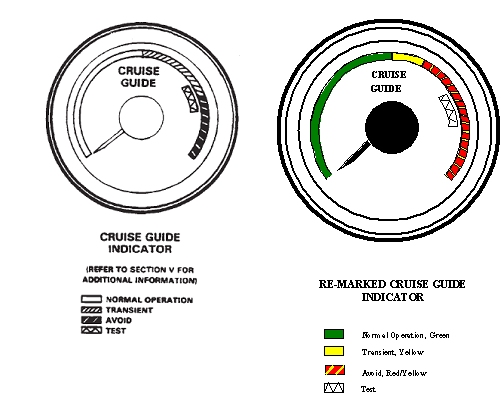

1.1.1. Following combat operation of CH-47D aircraft in Iraq and in the mountains of Afghanistan,

pilots reported that continuous flight operations were conducted with the cruise guide indicator (CGI)

in the transient region, accompanied by excursions into the avoid region, usually encountered in turbulence.

1.1.2. The CGI instrument provides a visual indication of loads incurred on critical dynamic components

in flight. It is divided into three bands; normal (green band), transient (yellow band), and avoid

(red/yellow striped band). Numerous operations, were reportedly conducted at high gross weights, extreme

aft center of gravity conditions, high torques, airspeeds exceeding VH, and at high density altitudes. The

impact of operation in the upper regions of the yellow (transient) band and any area in the red/yellow (avoid)

band of the CGI results in a significant decrease in the available fatigue life for the critical safety items on

the rotor controls and drive components. The reductions in available fatigue lives are dependent upon

component loads, aircraft loads, and the amount of time spent under these conditions.

1.2. Message Purpose -

1.2.1. Advise flight crews on operational limits of the CGI.

1.2.2. Require re-marking of the CH-47D CGI.

1.2.3. Require a one time visual inspection of the instrumented, aft, fixed link, part number (P/N) 414C3056-3.

2. eND ITEMS AFFECTED - All CH-47D Aircraft.

3. ASSEMBLIES/COMPONENTS/PARTS AFFECTED -

..Nomenclature Part Number NSN

..Cruise Guide Indicator Cockpit Display

152BUA34-2 6610-01-118-7577

114vs805-3 6610-01-118-7577

..Aft Fixed Link Actuator Assembly

414c3056-3 1615-01-117-1135

..Aft Fixed Link Rod End

114CS123-1 3120-00-110-8542

.

...................NOTE...................

....When complying with the requirements of this message,

....complete forms and records entries IAW DA PAM 738-751.

....ULLS-A units will use appropriate "E" forms.

4. Initial TAMMS (the army maintenance management system) compliance requirements -

4.1. Upon receipt of this message make the following entry on the DA Form 2408-13-1: Enter a Red

Horizontal Dash //-// status symbol with the following statement: "Comply with requirements of

CH-47-04-ASAM-02 before [####.#] aircraft hours, but NLT 13 May 2004." (Calculate [####.#]

as current aircraft flight hours plus 10 hours). Commanders who are unable to comply with the

requirements of this message within the time frame specified will upgrade the affected aircraft status

symbol to a Red //X//.

...................NOTE...................

....The TAMMS compliance reporting form is available at

...."www.redstone.army.mil/sof/tamms.xls" (use lower case

....letters only) or may be obtained from the units

....servicing LAR. Alternate forms may be approved by

....the AMCOM SOF Compliance Officer.

...................NOTE...................

....The TAMMS Compliance Report only confirms the unit has

....made the initial logbook entry for assigned aircraft.

....TAMMS Compliance Reports will include aircraft serial

....numbers (in numerical order), date of entry on DA Form

....2408-13-1, unit address, local POC name and phone number.

4.2. TAMMS Compliance Report - Submit TAMMS compliance report via priority email to

"safeadm@redstone.army.mil" 6 May 2004 from the message date IAW AR 95-1. If email is not

available, the report may be faxed to: SOF Compliance Officer at DSN 897-2111 or (256) 313-2111.

5. TASK/INSPECTION COMPLIANCE REPORTING REQUIREMENTS -

...................NOTE...................

....The Task/Inspection Reporting Form is available at ...."www.redstone.army.mil/sof/log.xls" (use lower case

....letters only) or may be obtained from the units

....servicing LAR. This report will cite the message

....number, date of inspection, aircraft serial number,

....aircraft hours, component serial number, component

....hours, and results of the inspection.

5.1. Aircraft - Submit Task/Inspection Compliance Reports as follows -

5.1.1. Initial Report - Submit Task/Inspection Compliance Report for this message to Log POC NLT 24 May 2004.

This report will be submitted using the Reporting Form IAW the note above.

5.1.2. Follow-on Report - Provide a report using the Reporting Form above to the Tech POC if the

limits of para 7.4 have been exceeded.

5.2. Retail Stock (Installation level and below) - N/A.

5.3. Wholesale Stock (Including Depot stock, Depot Maintenance and Single Stock Fund) - N/A.

6. SPECIAL PROVISIONS TO MESSAGE REQUIREMENTS (AIRCRAFT) -

6.1. Aircraft In AVUM, AVIM, Or Depot Level Maintenance - Commanders, Facility Managers and

Contractors will not issue aircraft until they are in compliance with this message.

6.2. Aircraft at Contractor Facility - Contractor facilities will inspect DD 250 aircraft prior to those aircraft

departing for ferry to final destination.

6.3. Aircraft In Transit - Unit Commanders in receipt of deployment orders and are unable to comply prior

to the date specified in Para 4.1 may defer initial requirements IAW surface/air shipment or ferry status

instructions, as appropriate.

6.3.1. Surface/Air Shipment - Comply with message requirements within 10 flight hours/14 days of arrival.

6.3.2. Ferry Status/Aircraft Away From Home Station - Comply with message requirements within 10

flight hours/14 days of arrival

6.4. Maintenance Trainers (Category A and B) - N/A.

6.5. Aircraft on Red //X// Status Symbol may be maintained in flyable storage. Ground run-ups at normal

operating rotor rpm are authorized.

7. TECHNICAL PROCEDURES/INSTRUCTIONS -

7.1. Unit Commanders are to ensure flight crews are briefed on flight operations with the CGI in the

yellow (transient) band and the prohibition of flight operations in the red/yellow striped (avoid) band.

7.1.1. Instruction must ensure a thorough understanding of the CGI and adherence to the operator's

manual limitations detailed in TM 1-1520-240-10, Paragraphs 2-14-2, 2-14-3, 5-2-2, 5-2-5, 5-5-2,

5-5-3, 5-6-2, 7-1-3, 7-7-2, 7A-1-2, 7A-1-3, and 7A-7-2. In addition to the -10 paragraphs, the

following supplemental information is provided on the CGI cockpit display:

7.1.2. Operation in any area in the red/yellow striped avoid band of the CGI results in a significant

decrease in the available fatigue life for the critical safety items of the rotor controls and drive components.

7.1.3. The reductions in available fatigue lives are dependent upon component loads, aircraft loads, and

the amount of time spent under these conditions.

...................NOTE...................

.....To re-mark the Cockpit Cruise Guide Indicator, Cockpit

.....Display, removal is not necessary.

...................NOTE...................

....If Figure 1 is not visible at the bottom of this message,

....it can be viewed at (use lower case letters only)

...."https://ams14.redstone.army.mil/safety/sof/pic/c47a0402.pdf

....or "https://www.chinook.redstone.army.mil/logon.asp", or

....contact the Logistical POC in Para 13.

7.2. Re-marking of the CH-47D CGI, Part Numbers 152BUA34-2 or 114VS805-3 shall be performed

within 10 flight hours/14 days per the instructions below.

7.2.1. Utilizing Figure 1, cut out the "RE-MARKED" cruise guide indicator template.

7.2.2. Cut out the red/yellow striped (avoid) band from the Figure 1 "RE-MARKED" CGI template.

7.2.3. Center the "RE-MARKED" template on the aircraft CGI (P/N 152BUA34-2 or 114vs805-3).

7.2.4. Tape the outside edges of the "RE-MARKED" template to the CGI.

7.2.5. Apply red instrument marking tape to the CGI display glass at the location where the red/yellow

striped band was removed from the Figure 1 template. If instrument tape is unavailable then a piece of

red tape placed on the glass at the beginning of the new red/yellow striped region denoted by the

"RE-MARKED" template is sufficient.

7.2.6. Remove the "RE-MARKED" template and outside edge tape to detach the template from the

CGI display.

7.2.7. To ensure the CGI glass is always positioned correctly, a torque stripe (also known as

Slippage Mark)shall be applied extending from the outer edge of the display glass to the edge of

the instrument.

...................NOTE...................

....Measuring with a protractor placed in the center of the

....gauge, the red band of the new avoid region begins at 63

....degrees above horizontal.

....The Red Band Arc length of the new avoid region is 1 7/16".

....The new Yellow Band Arc is 5/16" long.

...................NOTE...................

.....The yellow band on the re-marked CGI represents

.....100% to 120% rotor control/drive system design load.

.....The red (avoid) band on the re-marked CGI

.....begins at 120%.

7.3. If environmental conditions and/or mission requirements result in flight operations with the CGI

registering continuously (greater than 45 seconds) in the newly re-marked YELLOW (transient) band,

the flight crews shall take action to return to operations in the GREEN (normal)band of the CGI.

No forms entries need be made.

7.4. If environmental conditions and/or mission requirements result in flight operations with the CGI

registering continuously (greater than 45 seconds) in the newly re-marked RED (avoid) band, the flight

crews shall take action to return to operations in the green band of the CGI.

7.4.1. Flight crews shall record the estimated time, airspeed, pressure altitude, temperature,

gross weight, and approximate needle position in the upper or lower half of the avoid region on

DA Form 2408-13-1. This information shall be provided IAW para 5.1.2 as soon as possible to

the technical POC in Para 13 to determine maintenance action impact on a case by case basis.

7.4.2. Upon mission completion, enter a Circle Red //X// status symbol on the DA Form 2408-13-1

with the following statement: "Operate aircraft IAW para 7.4.2 of CH-47-04-ASAM-02."

Aircraft restricted to operations within the Inoperative Cruise Guide Indicator Envelope IAW

TM 1-1520-240-10, paragraphs 5-2-5, 5-5-2, 5-5-3, 5-6-2, 7A-1-2, and 7A-1-3).

.......................NOTE.................

.....The visual inspection of the aft fixed link rod ends

.....(P/Ns 414c3056-3 and 114CS123-1) may be accomplished while

.....the components are installed on the aircraft.

...................WARNING................

.....If visual inspections are to be performed on aircraft,

.....ensure no FOD enters the rotor head assembly.

7.5. Parts Inspection - For all CH-47D aircraft, visually examine the installed aft instrumented link

rod ends (P/N 114CS123-1), for bending/distortion, cracks, and other obvious defects. Visually

examine external rod end bearing threads for damage. No thread root damage is permitted on the

bearing threads. Any damage requires removal of the instrumented link assembly, per

TM 55-1520-240-23-5, Chapter 6 and disposition in accordance with Para 10.4.

7.6. The inspection is complete when:

7.6.1. All assigned pilots and aircrew are briefed on the requirements of this message

7.6.2. The CGI is modified in accordance with Para 7.2.

7.6.3. The applicable inspections in Para 7.5. have been performed.

7.7. Clear the initial entry from Para 4.1 and note compliance on DA Form 2408-5-1

( Rod End Bearing) and DA Form 2408-15 .

8. PROCEDURES/INSTRUCTIONS FOR ASSEMBLIES/COMPONENTS/PARTS

IN WORK OR IN STOCK (AT ALL LEVELS INCLUDING WAR RESERVES) - Annotate

the serviceability tag with: "Message CH-47-04-ASAM-02, Transient And Avoid Bands Of

The Cruise Guide Indicator, not complied with". Do not remove original condition tags.

9. SPECIAL TOOLS AND FIXTURES REQUIRED - N/A.

10. SUPPLY/PARTS (Requisition/Disposition) -

10.1. Parts Required -

..Nomenclature Part no./NSN Qty Cost ea. Total $

AFT Fix Link 414C3056-5/1615-01-117-1135 1 $6312.00 $6312.00

Total Cost Per Aircraft = $6312.00

10.2. Bulk and consumable materials -

Nomenclature Part Number NSN

Tape, Pressure Sensitive Adhesive RED

1872M 7510-00-015-0821

10.3. Requisitioning instructions - Requisition replacement parts using normal supply procedures.

All requisitions shall use Project Code (cc 57-59) "X2Q" (X-Ray-Two-Quebec).

...................NOTE...................

....Project Code "X2Q" is required to track and establish

....a data base of stock fund expenditures incurred by

....the field as a result of message actions.

10.4. Disposition of discrepant parts/components - Unit will submit a CAT 1 QDR with a tag

referencing this message, the serial number of the part, and the aircraft serial number. The

discrepant parts/components shall be held pending disposition instructions from Technical POC

in Para 13. If instructed to dispose of using normal supply procedures, all turn-in documents

must include Project Code (cc 57-59) "X2Q" (X-Ray-Two-Quebec).

10.5. Disposition of hazardous material - N/A.

11. MAINTENANCE APPLICATION -

11.1. Category of maintenance - AVUM

...................NOTE...................

....The time stated below does not include time for

....Maintenance Operational Checks, Maintenance Test

....Flights, or Flight Crew briefings.

11.2. Estimated time required -

11.2.1. Time to complete inspection - total of 2 man-hours using 2 persons with 1 hour per end item.

11.2.2. Time for repair/replacement - total of 12 man-hours using 3 persons with 4 hours downtime

per end item.

12. Publication requirements -

12.1. References -

12.1.1. AR 95-1.

12.1.2. AR 200-1.

12.1.3. DA Pam 738-751.

12.1.4. TM 1-1520-240-10.

12.1.5. TM 55-1520-240-23.

12.2. Publication Changes -

12.2.1 TM 1-1520-240-10 shall be changed to reflect this message. A copy of this message will

be used as authority to implement the change until the official change is received. Additionally, a

copy of this message will be inserted into the Aircrew Reading File until the official TM

changes are received. Specific changes to the -10 are as follows:

12.2.1.2. Change Figures 2-14-1 and 5-2-1 to reflect the same length red/yellow striped arc

as in Figure 1 "RE-MARKED" gage. Measuring with a protractor placed in the center of the gauge,

the red band of the new avoid region begins at 63 degrees above horizontal. The Red Band Arc

length of the new avoid region is 1 7/16". The new Yellow Band Arc is 5/16" long.

12.2.1.3. Paragraph 5-5-1 shall be modified to insert the following statement, "Any excursion

into the RED band of the cruise guide indicator for more than 45 seconds requires an entry on

the DA Form 2408-13-1. Provide the following information: Aircraft gross weight, FAT,

Pressure Altitude, total time in the red zone, and needle position within the red zone

(i.e. lower half or upper half).

12.2.2. TM 55-1520-240-23 Task 8-91, Page 8-288 add the following note: Ensure instruments

are marked in accordance with TM 1-1520-240-10 limitations.

13. Points of contact -

13.1. Technical POCs are -

13.1.1. Primary - Robert G. Duarte, AMSRD-AMR-AE-C, DSN 645-6194 Or

(256) 955-6194, Datafax is (256) 313-4726.

E-Mail is "Robert.Duarte@peoavn.Redstone.Army.Mil".

13.1.2. Alternate - Tim Rickmeyer, amsRD-AMR-ae-c, DSN 897-8040, or (256) 313-8040.

Fax is 256-313-4726.

Email is "timothy.rickmeyer@peoavn.redstone.army.mil".

13.2. Logistical POCs are -

13.2.1. Primary - Bill Olson, SFAE-AV-CH-CS, DSN 897-0721 or (256) 313-0721.

Fax is 897-4726 or (256) 313-4726.

Email is "william.olson@peoavn.redstone.army.mil".

13.2.2. Alternate - Norm Huston, SFAE-AV-CH-CS, DSN 897-0752 or (256) 313-0752.

Fax is 897-4348 or (256) 313-4348.

Email is "norm.huston@peoavn.redstone.army.mil".

13.3. Wholesale Materiel POC (spares) is Geri Reddy, AMSAM-MMC-AV-CA, DSN 897-1454

or (256) 313-1454. Fax is DSN 897-1106. Email is "geri.reddy@us.army.mil".

13.4. Forms and Records POC is Ms. Ann Waldeck, amsam-mmc-ma-nm, DSN 746-5564

or (256) 876-5564. Fax is DSN 746-4904 or (256) 876-4904.

Email is "ann.waldeck@redstone.army.mil".

13.5. Safety POCs are -

13.5.1. Primary - Frank Rosebery (Saic), Amsam-Sf-A, DSN 788-8631 or (256) 842-8631.

Fax is DSN 897-2111 or (256) 313-2111. Email is "frank.rosebery@redstone.army.mil".

13.5.2. Alternate - Russell Peusch, amsam-sf-a, DSN 788-8631 or (256) 842-8632.

Fax is DSN 897-2111 or (256) 313-2111. Email is "russell.peusch@redstone.army.mil".

13.6. Foreign Military Sales POC is Mr. Ronnie W. Sammons, amsam-sa-as-ut, DSN 897-0875

or (256) 313-0875. Fax is DSN 897-0411 or (256) 313-0411.

Email is "ronnie.sammons@redstone.army.mil".

13.7. After hours, contact the AMCOM Operations Center (AOC) DSN 897-2066/7

or (256) 313-2066/7.

...................NOTE...................

....A listing of published safety messages can be viewed at

...."https://ams14.redstone.army.mil/safety/sof/index.html".

....This is a secured website which requires an Army Knowledge

....Online (AKO) ("www.us.army.mil") ID and password.

...................NOTE...................

....If figure 1 below has been deleted or is not available go

....to (use lower case letters only) ...."https://ams14.redstone.army.mil/safety/sof/pic/c47a0402.pdf

....or "https://www.chinook.redstone.army.mil/logon.asp".

CH-47-04-ASAM-02

UNMARKED CGI RE-MARKED CGI

...................NOTE...................

....Insure that the diameter of the diagram matches the

....diameter of the gauge. The inner diameter of the bands is 1.4".

....Measuring with a protractor placed in the center of the

....gauge, the red band of the new avoid region begins at 63

....degrees above horizontal. The Red Band Arc length of the

....new avoid region is 1 7/16". The new Yellow Band Arc is

....5/16" long.